Empty container repositioning is both inefficient and costly. If you want to be a part of the solution, read this blog to learn how to avoid empty shipping container moves altogether by leasing out your units one way.

Did you know that every third shipping container is transported empty? That’s 60 million empty container moves a year.

We know you don’t want to add to these numbers. And you don’t have to. At Container xChange, the largest global shipping container marketplace, we’ve got 1,700+ vetted companies just waiting to connect with you.

Whether you want to avoid the hassle of shipping your containers empty, or need to lease containers for one-way moves, we’ll match you with the right partner in no time at all. The best part? You can negotiate rates, per diem charges, and free days directly with the company—no middlemen involved!

If you want to see our marketplace live in action, try our public search below to find container users or leasing deals that match your criteria now.

What is empty container repositioning?

Empty container repositioning involves moving empty units from an area with a Surplus Shipping Containers to an area with a deficit. For container owners, this has a substantial economic downside.

Every year, the process of moving empty units costs the shipping industry more than $20 billion. That’s more than 12% of operating costs for shipping lines. And it’s probably why you’re here, trying to find a solution to avoid this expensive problem altogether.

To understand this phenomenon better, imagine this scenario: You have 200 containers in Hamburg that need to be moved to Shanghai for export cargo. The problem? None of your northern European customers currently need these units for exports.

This means you have to move your empty containers from Hamburg to Shanghai, incurring considerable handling charges at terminals and ports, along with storage and maintenance at warehouses, inland transportation, and seaborne repositioning costs.

You might have been in this situation at some point. And you’re far from being the only one.

In general, European and American ports experience container surpluses often, while Asian ports regularly face shortages.

Luckily, there’s a solution: leasing containers for one-way moves. Not only will this help you avoid the high costs of repositioning empty containers, but also reduce port charges.

By leasing containers for one-way trips, you leave the container at its destination, eliminating the need for costly returns, and minimizing handling fees at ports. Like what you just read? We’ll deep dive into this later in the blog, but first, let’s understand what causes empty container repositioning.

If you want to know how to avoid empty container repositioning right now, (#how-to-avoid-empty-container-repositioning) to skip ahead.

What causes empty container repositioning?

Here are 3 main factors that contribute to empty container moves:

Trade imbalances

Trade imbalances occur when regions export more cargo than they import, and vice versa. This leads to a surplus of empty units in importing regions, which then need to be repositioned to exporting regions to keep up with demand.

Due to the Red Sea Shipping, we’re seeing a major surge in container volumes leaving China. In June this year, 1.36 million TEUS were moved from China to the US—the highest cargo volume ever recorded in a single month on this route.

This has also led to spikes in leasing rates. According to Drewry, freight rates in June 2024 increased by $585 to $5,975 per 40ft container between Shanghai and Los Angeles. And rates from Shanghai to New York rose by $379 to $7,214 per 40ft container.

So as you can see, trade imbalances not only affect container logistics, but also have a direct effect on shipping costs.

Seasonal demand fluctuations

Fluctuations in container demand are often due to seasonal factors, such as agricultural harvests or holiday exports. They can also be caused by political instability and war.

This results in periods where containers are abundant in one location and scarce in another. These fluctuations can sometimes be anticipated, but at other times they are completely unpredictable.

Peter Sand, Chief Analyst at Xenata, says: “The conflict in the Red Sea has brought a major shift in the traditional seasonality of ocean supply chains, with concerned shippers rushing to import as many goods as they can earlier in the year.”

port congestion and logistics inefficiency

High traffic volumes, along with inefficient cargo handling at ports, often leads to port congestion.

Over the past few months, we’ve seen high levels of congestion at ports in China, the UAE, Canada, and South Africa. Waiting times in Chinese ports such as Shanghai and Qingdao were at an all-time high in May, at up to five days to berth.

With port congestion, shippers can end up paying extremely high port charges, on top of already high freight rates.

Luckily, there’s a way to avoid the hefty port charges for containers that come with congestion—by using the xChange leasing marketplace. Keep reading to find out more.

How to avoid empty container repositioning and save on port charges

As a supplier who wants to avoid empty container repositioning, leasing out your containers one-way is the ultimate solution. And the xChange platform is the perfect platform to facilitate this.

You simply list your units on the marketplace, and wait for users to reach out to you. Once they do, you decide on the pick-up charges, free days and other terms together. So you get to avoid moving your units empty, and make a profit at the same time!

As a container user, you can also save big leasing by SOC containers instead of COCs (Carrier Owned Containers) for one-way moves on xChange. This is because using COCs leaves you liable to costly port charges like demurrage and detention in the case of delays and port congestion, but using SOCs does not.

With SOCs, you basically ‘bring your own container’, instead of using the carrier’s units, and can avoid these charges altogether. You also get to decide on the pick-up charges, per diem charges and free days along with the supplier. All costs can be settled before your shipment sets off, so you won’t be in for any surprises later on.

Leasing SOCs also gives you more freedom than COCs, as you’ll be able to ship goods over longer distances and to more remote locations.

So what are you waiting for? Connect with 1,700+ vetted partners on xChange to make container leasing deals that work for everyone. Click below to get started today.

Container triangulation: Another way to avoid empty container moves

Container triangulation is another method of avoiding empty container moves. It involves reusing a container for a new shipment immediately after it’s been emptied at the destination port. In this way, the container isn’t returned to the origin or depot, and empty repositioning is avoided.

Container triangulation aims to find a new shipment for an empty unit, close to where it was emptied, rather than returning it. This means that the distance the container is moved empty overall is drastically reduced.

How tech advancements changed container management strategies

Although challenges like empty container repositioning continue to persist, tech advancements have drastically improved container management in recent years and will continue to do so. Here are some of the main ones to watch:

Real-time tracking: With IoT (Internet of Things) and GPS, it’s easier to track container movements in real-time. This helps to monitor and coordinate shipments, as well as predict potential delays and make alternative arrangements where needed.

Blockchain technology: Blockchain Shipping has helped to increase transparency and security in the shipping world. This means more trust between industry players and better cooperation.

Port automation: Port automation has drastically improved both the safety and efficiency of port operations, increasing turnaround times and reducing delays.

Online container sharing platforms: Container sharing platforms allow container owners and users to connect and work together to avoid empty container moves. Online marketplaces like Container xChange make it possible to match owners and users safely and efficiently and decide on the terms and conditions together.

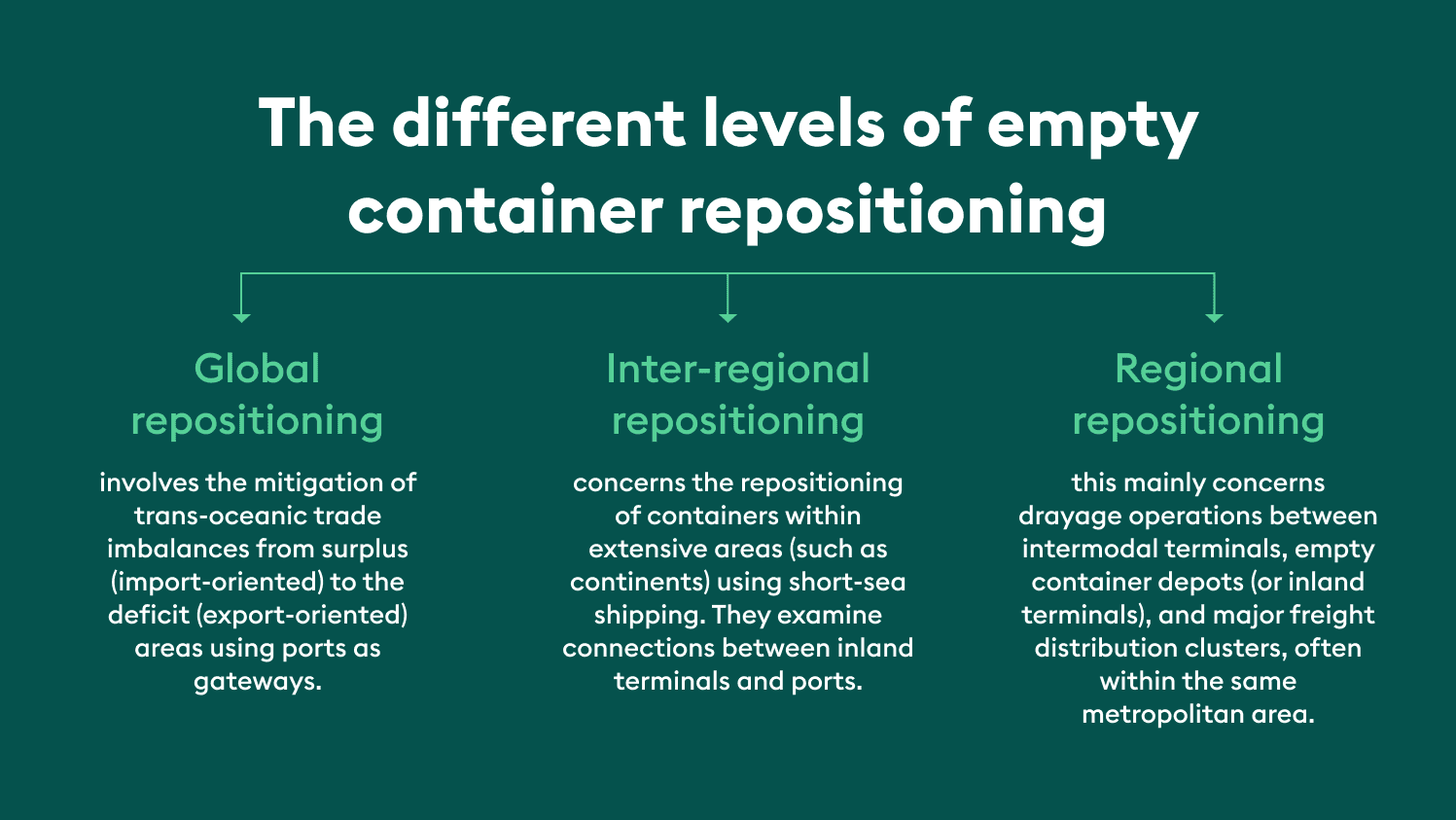

Levels of empty container repositioning

We’ve covered the causes and how you can avoid empty container repositioning. But before we lead you to the end of the blog, here’s some add-on information about the levels of empty container repositioning:

- Global repositioning

- Inter-regional repositioning

- Regional repositioning

Now that we’ve got the full lowdown on the problem of empty container repositioning and how to avoid it, let’s check out just how easy it is to connect with partners on xChange below.

Save costs on empty container repositioning and get the best deals on xChange

Whether you want to find partners to lease your containers and help you avoid empty container moves, or lease containers yourself, it’s easy to do so in just three simple steps.

Add your containers or browse offers

If you’re a supplier and want to learn more, the first step is to add your containers to the platform, with all of the necessary details, such as container type, condition, size, pick-up locations, and pick-up charges. Your offer will be instantly available. All you have to do is wait for partners to match and reach out.

If you’re a container user and want to lease containers for one-way moves, hop onto the platform, select container type, pick-up, and drop-off location, and start browsing available offers. You’ll be able to see details such as location and company up front.

What’s more, you can check out the xChange members of any partner before deciding to work with them.

Negotiate a deal that suits everyone

On xChange, partners can connect directly on the platform to discuss all of the finer details of the deal together—no middlemen involved, no sneaky added commissions. This means that only you and the partner decide on the final pick-up charges, per diem charges, and free days. It’s a win-win!

Make and receive safe payments

Once the deal has been settled between partners, all payments can be made on xChange, using our learn more about xChange Wallet. This means you’ll only have one payment partner, and all payments are credited in real-time.

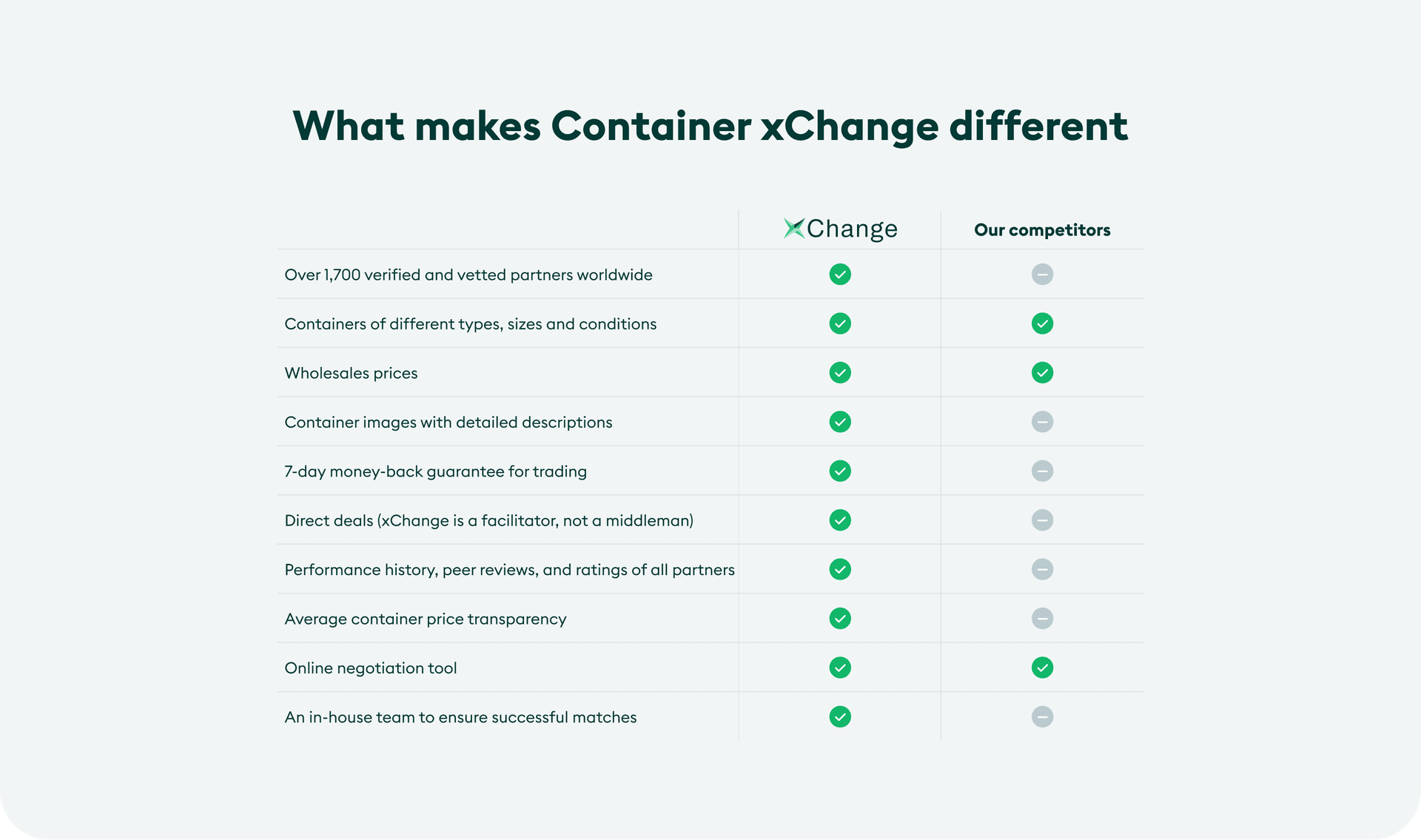

Wondering what makes xChange different from other platforms? Here’s a quick summary of the benefits you’ll enjoy once you subscribe.

Ready to save money for your business by connecting with vetted partners on xChange? Click below to set up your free demo with our expert team now. You’ll get a tour of the platform and learn how our marketplace can help you avoid empty container repositioning and save on hefty port charges once and for all.

What is empty container repositioning?

Empty container repositioning refers to moving empty containers from an area with a surplus of containers to a location with a deficit of containers. Moving empty containers is both expensive and inefficient.

How can empty container repositioning be avoided?

Empty container repositioning can be avoided by matching container owners with container users who need to move cargo one way. Here, the container owner avoids moving units empty, and the container user transports their cargo for a reduced rate.

How can you reduce empty container repositioning costs?

Reducing empty container repositioning costs involves engaging in container sharing such as leasing out your units one-way, implementing real-time container tracking, and strategic container positioning, among other things.

![Empty container repositioning: How to save on costs with SOCs [+Get best rates]](/_next/image?url=%2Fblog%2Fempty-container-repositioning-featured.jpg&w=1920&q=75)